The HDX-M dust removal system uses different filtering materials based on the properties of dust to intercept and retain dust in dusty gases. It also uses collision, diffusion, static electricity, sedimentation, and other functions to purify the dusty air. At the same time, pulse spraying and other cleaning methods are used to remove dust attached to the surface of the filter material, restoring the filtering ability of the filter material. When cleaning, the machine does not stop and does not affect production.

It has the advantages of high dust removal efficiency (dust removal rate ≥ 99.5%, dust emission concentration meets the standard), wide adaptability, no secondary pollution, and easy maintenance. The main body of the dust remover adopts the standard module combination structure, which can flexibly increase the air volume to be treated according to the use needs, while the original main body does not need to be changed, which has the advantage and progressiveness of adapting to the use unit and future development.

Application field

The HDX-M dust removal system is suitable for treating dust containing waste gases at room temperature, low humidity, low oil content, and low corrosion. By upgrading, optimizing, and adding supporting equipment to the filter bags, it can also handle high temperature and corrosive dust containing waste gases.

Principle Analysis

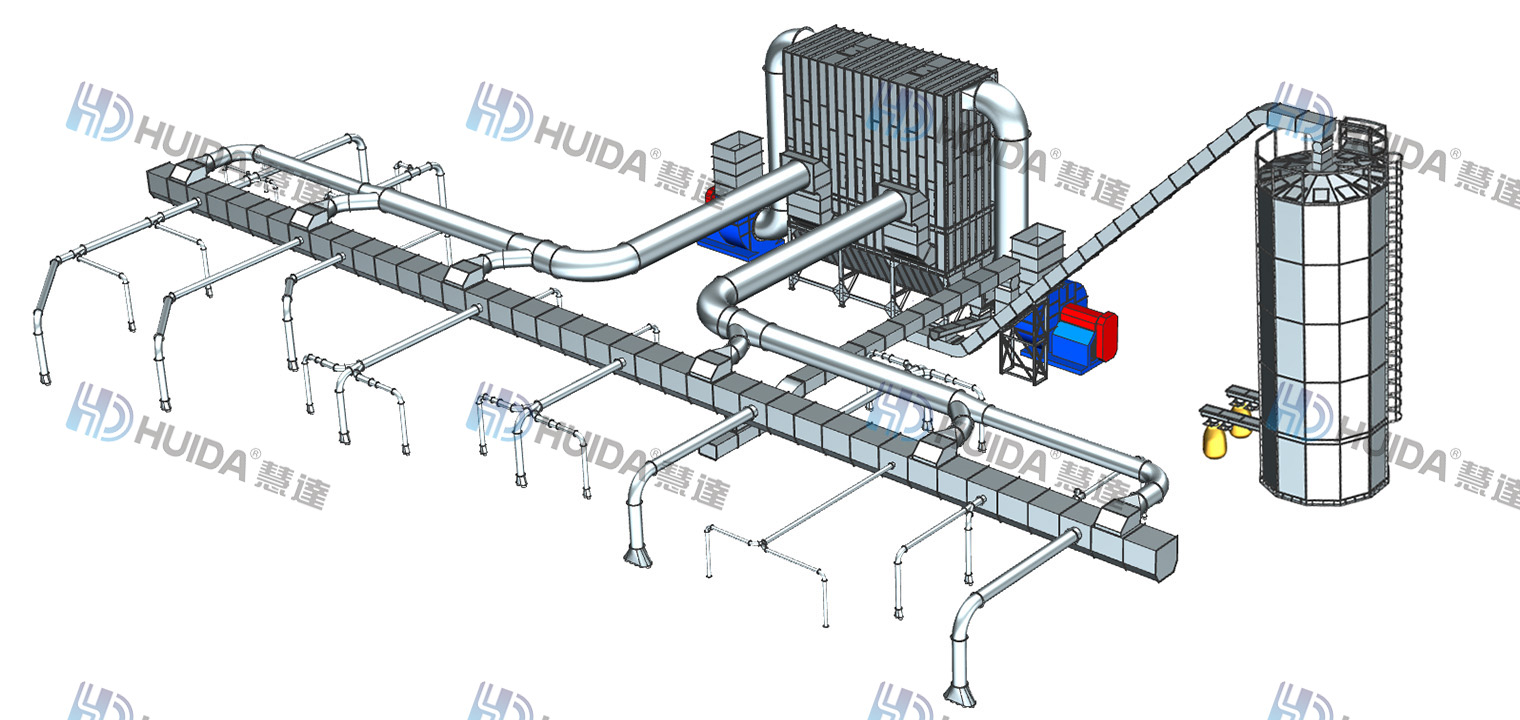

The HDX-M dust removal system mainly consists of several parts, including a dust collector, intelligent control system, fan, constant pressure settling conveying tank, dust suction pipeline network, dust conveying system, storage bin, etc. During the operation of the dust removal system, dust generated at various dust points in the production site is captured and transported to the settling tank through the suction pipe network. The coarse and heavy dust blocks will settle to the bottom of the tank, be discharged by the conveying system, and enter the dust conveying system. Light and fine dust enters the pulse bag filter dust collector with the air. Pulse bag filter dust collector mainly uses high-density filtering materials to filter and separate dusty air. At the same time, an online pulse spraying system is used to guide compressed air to spray the filter bag in the opposite direction. By utilizing the rapid expansion and vibration of the filter bag during spraying and the effect of the reverse airflow, the dust is shaken to the bottom of the dust collector, and then discharged by the discharge system and merged into the dust conveying system for subsequent processing.

Technical features:

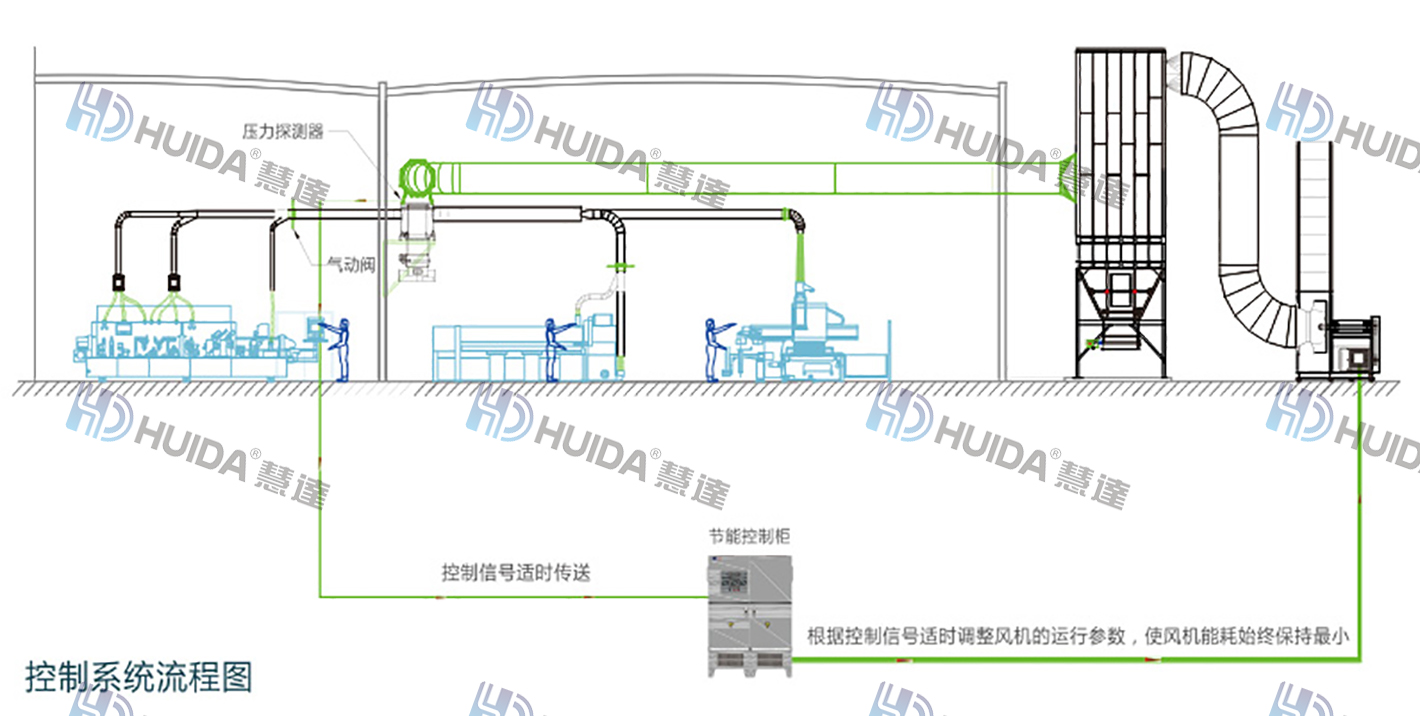

Introduction to Intelligent Control System:

Adopting fully automatic frequency conversion speed control technology, the precise pressure signal sensor set at an appropriate position in the suction pipe network provides timely signals. Based on the actual required air volume and pressure of the suction pipe network, the number of induced draft fans and fan speed of the dust removal system are automatically adjusted, so that the air volume and pressure of the induced draft fan of the dust removal system always match the actual air volume and pressure required for dust suction in the production process, and the energy consumption in the actual operation of the system is always kept to the lowest, thus achieving the goal of automatic energy conservation.

System fault monitoring function:

1. Motor overload protection

2. Power outage detection

3. Shutdown detection

4. Chain breakage detection

5. Anti door opening protection

6. Fire protection

7. Material level detection

GSM alarm function:

The GSM alarm function is an effective combination of mobile communication technology and intelligent control systems. When a fault occurs, the GSM alarm in the system will immediately send the fault information to the device management personnel's mobile phone via SMS, or directly call the management personnel's phone number, so that the device management personnel can timely understand the fault information, so that the fault can be eliminated in the shortest possible time and minimize the losses caused by the fault.

All rights reserved ? 2021 Huida Environmental Protection Co., Ltd